All You Need to Know About Material Types in SAP Materials Management

by Yoann Bierling

There are various basic material types available by default in any standard SAP installation. This list can also be extended or customized with your own material types, as required by your business.

There are various basic material types available by default in any standard SAP installation. This list can also be extended or customized with your own material types, as required by your business.

What are the standard SAP material types, what are their main differences, why do they matter, and when can you learn more about SAP Materials Management? Let's find out!

When is Material Type used?

The material type is a piece of basic information for SAP, used by any product or service that will be handled by the business: bought, produced, or sold.

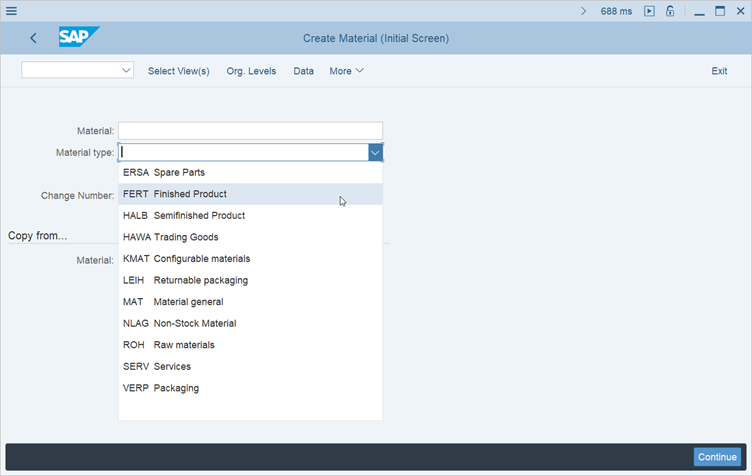

When creating any material in the system, it is mandatory to select its material type, whether from the list of standard options, or your company's customized options.

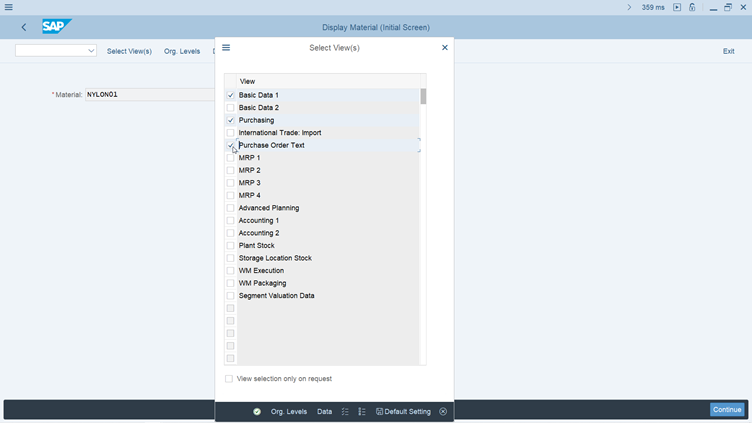

The main difference between material types will be reflected in the Material Views that can – or must – be opened for any material of this type that will be created later in the system.

Depending on the system customization that has been done, some views will simply not be allowed to be created for the product. For example, it would not be possible to create sales views for products that aren’t sold by the company or to add production data to a material that is not manufactured internally.

During the creation of a new material using MM01 transaction, it is mandatory to select a material type, to select the views and functionalities that will be available to that product or service.

Figure 2: Selection views to maintain for a given material

What are the basic material types and what do they mean?

FERT - Finished Goods

The FERT Finished Goods are one of the most important types of products for any business. They are generally the only ones, along with HALB, that can be sold externally on Ariba or to direct customers, and generate revenue, and ultimately a profit, if priced correctly.

A finished good cannot be used in production and in a Bill Of Material to create another product, as they are only used at the end of the production chain.

However, they could also be bought externally and be directly resold to customers, but in that case, it would be more convenient to use HAWA Trading Goods.

HALB - Semifinished Goods

The HALB Semifinished Goods are the second most important materials for most. They can not only be sold outside of the system but can also be used in production to create other Semifinished Goods or Finished Goods.

They can be created either in production by mixing raw materials and other semifinished goods or can be bought from suppliers.

The semifinished goods will have access to most views of the Material Master.

HAWA - Trading Goods

The HAWA Trading Goods are not manufactured by the company and are simply traded: bought from a supplier, eventually stored in the warehouse, and sold to customers, without any change applied to the product.

These products will not have any production planning-related views open in Material Master.

KMAT - Configurable Materials

The KMAT Configurable Materials are complex materials with variations, which are generally associated with a manufacturing process, such as a choice of paint color for a car, or a size for a clothing article.

They will have BOMs associated to allow for various configurations to be produced and will be sold to clients.

LEIH - Returnable Packaging

The LEIH Returnable Packaging materials are package products that are included with delivered goods and can be returned to the vendor, either for reusing or for legal reasons.

These products will be owned by their respective vendors during product exchange, and therefore not evaluated even while being counted in warehouse stock.

NLAG - Non-Stock Material

The NLAG Non-Stock Materials are products generally used for production or shipment preparation, that are often procured externally, but for which the usage is not directly counted: for example, nails or plastic wrap.

While these products are valued, bought and stock reorder is triggered, when necessary, they are not expected to keep an exact inventory track.

ROH - Raw Materials

The ROH Raw Materials are used in production, and technically only for internal manufacturing purposes. They are procured externally, bought on Ariba, from direct suppliers, or created by the business from scratch. They are parts of Bills of Materials that create either semifinished or finished goods, that can then themselves be sold to customers.

Typically, they will not have any sales views activated, as they wouldn't be sold to outside customers.

SERV - Services

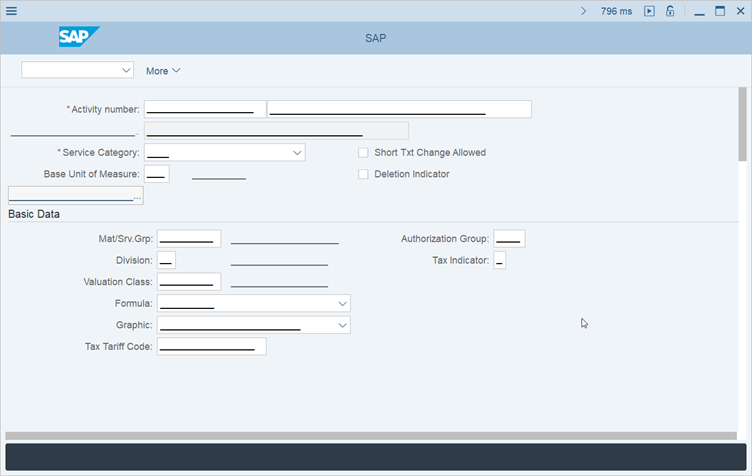

The SERV Services material code is used for intangible materials, that cannot be stored, transported nor stocked, such as software or testing.

They can be managed in a specific transaction suite, AC01 for creation, to allow for faster processing of these services that have no corresponding inventory views.

Figure 3AC01: Service creation transaction

VERP - Packaging

The VERP Packaging materials are used to pack finished goods together before shipping them to a customer.

Their most important characteristics are weight and volume, and they will directly impact the shipping conditions.

ERSA - Spare Parts

The ERSA Spare Parts products are procured externally but cannot be sold. Part of the PM, or Plant Maintenance, module they are used to maintain and repair production tools and machines.

While they will be valued based on their quantity and price, they can have purchasing Material Master views open. But of course, they cannot have Sales views, as they would not be a sales product.

How can you maintain material types?

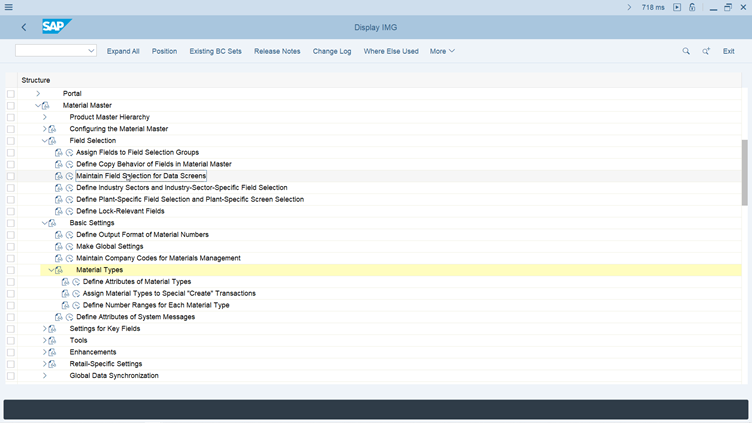

While most materials can use a predefined standard material type, it is often useful to maintain them to either create your own material types, change fields requirements, add custom fields, or select Material Master views associated.

All these customization options are available to system administrators and project business analysts in the SPRO transaction, under Logistics > Material Master.

Figure 4: Material type relevant customization options

The customization of a Material Master type could be the subject for a full course and must be handled with care, as it can have critical impacts on the whole system behavior, from Operational Procurement to sales through production.

To sum up: What should you know about Material Types?

The Material Types in SAP Materials Management are critical for business operators to create new materials in an SAP system.

Depending on the selection made, various views will be available for the material, and the product behavior will differ based on the customization done by the system administrators.

However, being able to recognize and understand the various Material Types is necessary, basic knowledge for any SAP user, as the materials used in all transactions will directly depend on this basic configuration.

In many cases, system errors can directly be coming from selling the material type. Issues also arise when various similarly named products are present in the system for separate diverse usages, even if they ultimately refer to the same article in real life.

Learn more about Material Type and their usage in SAP MM in our SAP Materials Management dedicated course!

by Yoann Bierling

More Blogs by Yoann Bierling

Four Steps to Effective SAP Data Cleansing

It's an inevitable problem. Over time, data gets messy. This inclu...

The 8 Basic Functionalities of SAP Ariba

Acquired by SAP in 2012 for $4.3 billion, the SAP Ariba netw...

What is the Plan-Buy-Pay Process?

What is the Plan-Buy-Pay Process? The Plan-Buy-Pay process, which i...

Related Blogs

The Bill of Materials (BOL) in SAP

If you work in a manufacturing environment, you are no stranger to the...

Four Steps to Effective SAP Data Cleansing

It's an inevitable problem. Over time, data gets messy. This inclu...

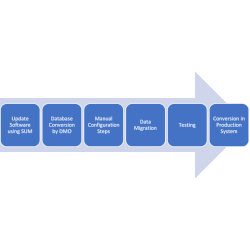

All about converting your ECC system to S/4Hana

SAP S/4Hana brought about a revolution in terms of SAP system architecture,...

.png)